- 817.295.6100

- 645 E. Renfro St., Burleson, TX 76028

- Mon - Fri: 8:00 - 5:00

did you know?

70% of our detailers have worked for us over 10 years.

Yep. It's true.

We've been at this since before there was Internet.

That's a long time.

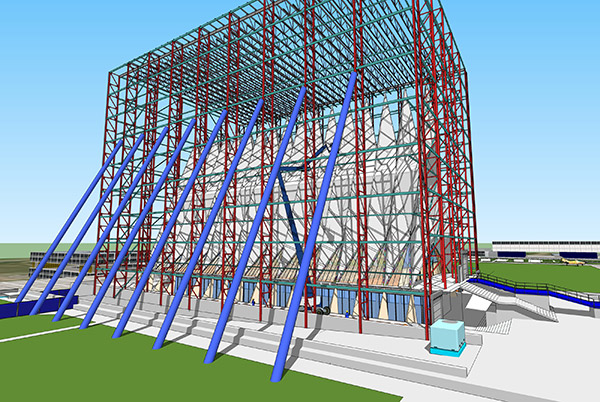

True turn key - our detailer, our steel, our crews, our cranes.

Your success.

Ever see a car fly? We once built a frame to support a car, then flew said frame with said car onto the roof at the Texas Rangers Stadium.

Just in a day’s work.

On average our team has steel done and ready to ship prior to the site being ready. Hmmm, how often is your fabricator waiting on you?

Or is it the other way around?

You could check on your next load of steel while, hmm well, in the “reading room”. How?

Ask us.

Most steel used in Commercial Construction is 92%+ recycled content.

Ask your concrete guy how much of their product is recycled.

Fabrication is the easy part. Managing the detailing process, proper sequencing, detailed erection planning, and a continuous effort to deliver on time or ahead of schedule is the magic.

Let us show you some.

Our problems should not be your problems.

We handle our problems, so they don’t become yours.

We did BIM before there were iPhones.

Truth.

Previous

Next

Menu